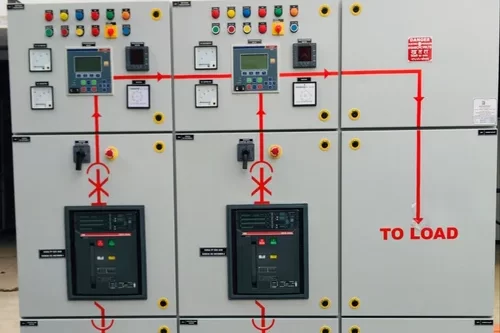

MCC Panel

An MCC panel, or Motor Control Center panel, is an assembly designed to control and distribute power to electric motors and other associated equipment in industrial and commercial applications. These panels are used in environments where multiple motors are required, such as in manufacturing plants, refineries, and large commercial buildings.

Key Functions of a MCC Panel:

- Centralized Motor Control: MCC panels house multiple motor control units (MCUs), each of which controls a specific motor. This centralized approach allows for easier management, operation, and maintenance of multiple motors from a single location.

- Protection: MCC panels include protective devices like circuit breakers, fuses, and overload relays that protect motors and wiring from electrical faults, such as short circuits, overloads, and phase imbalances.

- Starting and Stopping Motors: The panel provides control mechanisms for starting and stopping motors. This can include direct-on-line (DOL) starters, star-delta starters, soft starters, and variable frequency drives (VFDs), depending on the motor's requirements.

- Monitoring and Control: MCC panels are equipped with various monitoring devices, such as ammeters, voltmeters, and indicators, to monitor the performance of motors. They may also include PLCs (Programmable Logic Controllers) or other control systems for automated operation.

- Safety: Safety features such as emergency stop buttons, interlocks, and ground fault protection are integrated into MCC panels to ensure safe operation and to protect personnel from electrical hazards.

- Maintenance and Troubleshooting: MCC panels are designed to make maintenance and troubleshooting easier. Components like circuit breakers and contactors are often modular, allowing for quick replacement without affecting other parts of the system.

In an MCC (Motor Control Center) panel, various electrical abbreviations and symbols are used to represent components, functions, and electrical parameters. Understanding these is essential for reading electrical schematics and operating the panel.

AC – Alternating Current

DC – Direct Current

V – Voltage

A – Ampere (Current)

Hz – Hertz (Frequency)

kW – Kilowatt (Power)

kVA – Kilovolt-Ampere (Apparent Power)

PF – Power Factor

MCB – Miniature Circuit Breaker

MCCB – Molded Case Circuit Breaker

ELCB – Earth Leakage Circuit Breaker

RCCB – Residual Current Circuit Breaker

VFD – Variable Frequency Drive

CT – Current Transformer

PT – Potential Transformer

NO – Normally Open (Contacts)

NC – Normally Closed (Contacts)

OLR – Overload Relay

DOL – Direct On Line (Starter)

SPD – Surge Protection Device

PLC – Programmable Logic Controller

HMI – Human Machine Interface

SFU – Switch Fuse Unit

FWD – Forward (Motor Direction)

REV – Reverse (Motor Direction)

M – Motor

LS – Limit Switch

TB – Terminal Block

I/O – Input/Output

Circuit Breaker Symbol:Represents devices like MCB, MCCB, and ACB.

Contactor Symbol:Represents an electrically controlled switch used to control motors.

Overload Relay Symbol:Protects motors from overheating due to overcurrent.

Push Button Symbol:Represents control buttons, such as start/stop buttons.

Motor Symbol:Represents an electric motor.

Variable Frequency Drive (VFD) Symbol:Represents a VFD used to control motor speed.

Transformer Symbol:Represents a transformer that steps voltage up or down.

Relay Symbol:Represents a relay used to control circuits.

Fuse Symbol:Represents a fuse for protecting circuits from overcurrent.

Ground/Earth Symbol:Represents the grounding or earthing connection.

Power Supply Symbol:Represents the main power source.

Control Transformer Symbol:Represents a transformer used in control circuits to provide low voltage.

Terminal Block Symbol:Represents connection points for wiring.

Indicator Lamp Symbol:Represents status indicators such as ON, OFF, or fault conditions.

Limit Switch Symbol:Represents a switch that is activated by mechanical movement, used to control machinery limits.

Motor Control Center (MCC) panels are used in a wide variety of industries and applications where there is a need to control and manage multiple motors. These panels are essential for ensuring that motors operate efficiently, safely, and reliably. Below are some of the key uses of MCC panels:

1. Manufacturing Plants

Machinery Operation: MCC panels control and manage the operation of motors that drive various types of machinery such as conveyors, mixers, pumps, and compressors in manufacturing facilities.

Automation Systems: They are often integrated with automated systems to provide centralized control over multiple motors, improving efficiency and reducing manual intervention.

2. Water and Wastewater Treatment Plants

Pumping Systems: MCC panels control the motors that drive pumps used in water treatment, sewage treatment, and distribution systems. This includes controlling the flow of water through filtration systems, chemical dosing pumps, and sludge handling equipment.

Aeration and Mixing: In wastewater treatment, MCC panels manage motors that operate aerators and mixers, ensuring proper oxygenation and mixing of wastewater.

3. Oil and Gas Industry

Pumping Stations: MCC panels are used to control the motors driving pumps in oil pipelines, refineries, and offshore platforms. These pumps are critical for transporting crude oil, gas, and refined products.

Compressor Stations: They control motors that drive compressors used in gas processing and transportation, ensuring consistent pressure and flow in pipelines.

4. Mining Industry

Heavy Equipment Control: MCC panels manage motors that power heavy machinery such as crushers, conveyors, and grinding mills in mining operations. These panels ensure the reliable operation of equipment used in the extraction and processing of minerals.

Ventilation Systems: In underground mining, MCC panels control the motors driving ventilation fans, ensuring a safe and breathable environment for workers.

5. Power Plants

Auxiliary Systems: MCC panels control motors that operate auxiliary systems in power plants, such as cooling pumps, fans, and conveyors that handle coal or ash.

Boiler Feed Pumps: They manage the operation of motors driving boiler feed pumps, which are crucial for maintaining the steam cycle in thermal power plants.

6. Commercial Buildings

HVAC Systems: MCC panels control motors that drive heating, ventilation, and air conditioning (HVAC) systems in large commercial buildings, ensuring proper climate control and air quality.

Elevator Systems: They manage the motors that operate elevators, ensuring safe and efficient vertical transportation.

7. Food and Beverage Industry

Processing Equipment: MCC panels control motors that operate processing equipment such as mixers, grinders, conveyors, and packaging machines in food and beverage production.

Pumping Systems: They also control motors driving pumps used in the transportation of liquids, such as milk, juice, or beer, within the production facility.

8. Pharmaceutical Industry

Cleanroom HVAC Systems: MCC panels manage the motors that control airflow and filtration systems in cleanrooms, which are critical environments for pharmaceutical manufacturing.

Process Control: They are used to control motors in various stages of drug manufacturing, including mixing, grinding, and tablet compression processes.

9. Chemical and Petrochemical Plants

Reaction and Mixing Systems: MCC panels control motors that drive mixers, agitators, and pumps used in chemical reactions and mixing processes.

Safety Systems: They are often integrated with safety systems to ensure that motors operate within safe parameters, protecting both the process and personnel.

10. Agriculture

Irrigation Systems: MCC panels control the motors that drive pumps used in irrigation systems, ensuring efficient water distribution across agricultural fields.

Grain Handling: They manage motors in equipment used for grain drying, conveying, and storage, ensuring efficient handling of agricultural products.

11. Steel and Metal Industry

Rolling Mills: MCC panels control motors that drive rolling mills, ensuring precise control over the rolling process in steel and metal manufacturing.

Furnace Operations: They manage motors used in the operation of furnaces, including blowers and material handling systems.

12. Paper and Pulp Industry

Pulping Machines: MCC panels control motors in pulping machines, which are used to process raw materials into pulp for paper production.

Paper Machines: They also manage the operation of motors in paper machines, ensuring continuous and efficient paper production.

13. Transportation Systems

Railway Systems: MCC panels are used to control motors in railway systems, including motors for trains, signaling systems, and track switches.

Airport Baggage Handling: They control motors in baggage handling systems at airports, ensuring the smooth movement of luggage.

14. Data Centers

Cooling Systems: MCC panels manage the operation of motors driving cooling systems in data centers, which are critical for maintaining the optimal temperature of servers and IT equipment.

These applications demonstrate the versatility and importance of MCC panels in managing and controlling motor-driven processes across a wide range of industries.