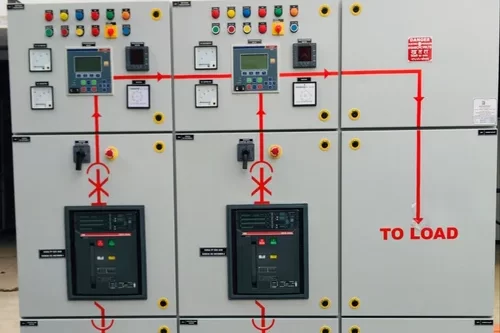

DRAWOUT MCC PANEL

A Drawout Motor Control Center (MCC) Panel is a type of electrical control panel that is used to control and manage the operation of motors and related electrical equipment. The “drawout” feature refers to the design where individual motor control units (or buckets) can be easily slid in and out of the MCC structure for maintenance, replacement, or upgrades without disturbing the rest of the system.

Key Features of a Drawout MCC Panel:

1.Drawout Units (Buckets):

Feature: Each motor control unit is housed in a separate compartment or “bucket” that can be easily pulled out (drawn out) from the panel.

Purpose: Facilitates easy maintenance, inspection, and replacement of motor control components without needing to shut down the entire MCC.

Benefit: Reduces downtime and enhances safety during maintenance activities.

2.Modularity:

Feature: The panel is designed in a modular fashion, allowing for easy customization and expansion.

Purpose: New units can be added, and existing units can be upgraded or replaced as needed, making the panel adaptable to changing requirements.

Benefit: Provides flexibility in configuring the MCC for different applications and load requirements.

3.Safety and Isolation:

Feature: When a unit is drawn out, it is automatically disconnected from the power source, ensuring the safety of personnel working on it.

Purpose: Prevents electrical accidents by ensuring that only the unit being serviced is de-energized while the rest of the system continues to operate.

Safety Mechanisms: Often includes interlocking mechanisms that prevent the unit from being removed while it is still live.

4.Standardization:

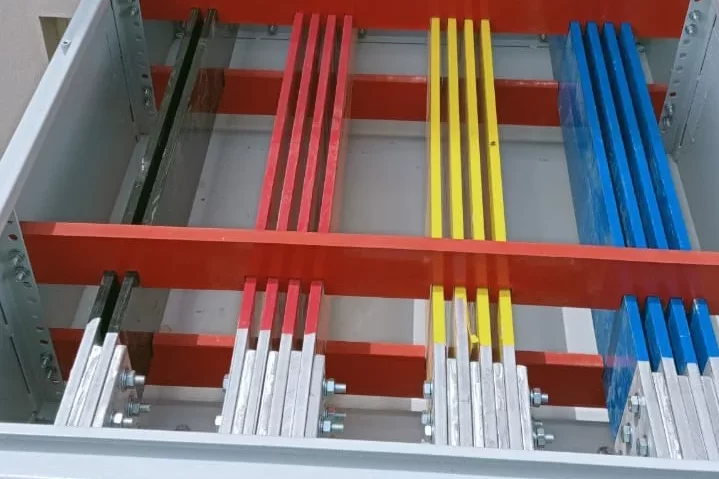

Feature: Typically follows standard designs and sizes, allowing for interoperability between different manufacturers’ components.

Purpose: Simplifies installation, maintenance, and component replacement.

Standards: Designed to meet relevant standards such as IEC, NEMA, or local electrical codes.

5.Control and Monitoring:

Feature: Each unit includes control components like circuit breakers, contactors, overload relays, and may also feature monitoring devices like meters and sensors.

Purpose: Provides comprehensive control and protection for motors, including starting, stopping, and monitoring operational parameters.

Integration: Can be integrated with automation systems for remote control and monitoring.

6.Ease of Maintenance:

Feature: Units can be easily removed and replaced without the need for extensive tools or shutdown of the entire panel.

Purpose: Simplifies maintenance tasks and allows for quick replacement of faulty components.

Benefit: Minimizes downtime and maintenance costs.

7.Compact Design:

Feature: Despite the drawout capability, the panel is designed to be space-efficient.

Purpose: Saves space in electrical rooms or control centers, making it suitable for installations where space is limited.

Application: Commonly used in industrial settings where space and accessibility are critical.

8.Customization Options:

Feature: Can be customized with different types of motor starters (e.g., direct-on-line, star-delta), protection relays, and communication modules.

Purpose: Allows for tailored solutions to meet specific application needs, such as varying motor sizes and control requirements.

Application: Suitable for various industries including manufacturing, oil & gas, water treatment, and more.

In a Drawout Motor Control Center (MCC) Panel, various electrical abbreviations and symbols are used to represent different components, functions, and electrical connections. These abbreviations and symbols help in the identification and understanding of the system’s design and operation. Below are some common electrical abbreviations and symbols found in a drawout MCC panel:

CB – Circuit Breaker

Used to protect the circuit from overload or short circuit.

MCB – Miniature Circuit Breaker

A smaller version of a circuit breaker used for low-power circuits.

MCCB – Molded Case Circuit Breaker

Provides protection for higher power circuits than MCBs.

OLR – Overload Relay

Protects motors from overheating due to overload.

VFD – Variable Frequency Drive

Controls the speed and torque of motors by varying the frequency and voltage.

SFU – Switch Fuse Unit

Combines a switch and a fuse to protect against short circuits.

CT – Current Transformer

Measures the current and provides a scaled down current for metering or protection.

PT – Potential Transformer

Measures the voltage and provides a scaled-down voltage for metering or protection.

NO – Normally Open

Refers to a switch or relay contact that is open (not conducting) in its default state.

NC – Normally Closed

Refers to a switch or relay contact that is closed (conducting) in its default state.

M – Motor

Represents the motor being controlled by the MCC.

DOL – Direct-On-Line Starter

A type of motor starter that directly connects the motor to the power supply.

SD – Star-Delta Starter

A motor starter that reduces the starting current by initially connecting the motor in a star configuration and later switching to delta.

AF – Auxiliary Contact Normally Open

Additional contacts in a relay or contactor used for control logic.

AL – Alarm

Indicates a fault or condition that requires attention.

PB – Push Button

A manually operated switch used for control operations like start, stop, or reset.

K – Contactor or Relay

A device used to control the connection of power to the motor.

MFM – Multifunction Meter

Used for monitoring various electrical parameters like voltage, current, power factor, etc.

SCADA – Supervisory Control and Data Acquisition

A system used for remote monitoring and control.

HMI – Human-Machine Interface

A user interface for interacting with the control system.

PLC – Programmable Logic Controller

An industrial computer used to automate processes.

RCD – Residual Current Device

Provides protection against earth faults.

Circuit Breaker Symbol ( )

Represents a circuit breaker in the panel diagram.

Fuse Symbol ( )

Represents a fuse used in the circuit.

Contactor Symbol ( )

Represents a contactor used to control the motor.

Overload Relay Symbol ( )

Represents an overload relay that protects the motor.

Motor Symbol ( )

Represents the motor that is being controlled.

Push Button Symbol ( )

Represents a push button used for start/stop operations.

Transformer Symbol ( )

Represents a current or potential transformer.

Resistor Symbol ( )

Represents a resistor used in the circuit.

Inductor Symbol ( )

Represents an inductor used in the circuit.

Capacitor Symbol ( )

Represents a capacitor used for power factor correction.

Ground Symbol ( )

Indicates a connection to the earth or ground.

NO Contact Symbol ( )

Represents a normally open contact in a relay or switch.

NC Contact Symbol ( )

Represents a normally closed contact in a relay or switch.

Meter Symbol ( )

Represents a meter used for measuring electrical parameters.

Alarm Symbol ( )

Represents an alarm indicator.

PLC Symbol ( )

Represents a Programmable Logic Controller in the circuit.

HMI Symbol ( )

Represents a Human-Machine Interface device.

Drawout Motor Control Center (MCC) Panels are widely used in industrial and commercial settings to manage and control electric motors and other related electrical equipment. Their “drawout” feature allows individual motor control units to be removed or inserted easily, making them particularly useful in environments where operational flexibility and maintenance efficiency are critical. Here are the primary uses of Drawout MCC Panels:

1. Motor Control:

Use: Centralized control of electric motors in various applications.

Example: Controlling conveyor belts, pumps, fans, and compressors in a manufacturing plant.

Benefit: Allows for the control of multiple motors from a single panel, improving operational efficiency.

2. Easy Maintenance and Replacement:

Use: Facilitates quick and safe maintenance, testing, and replacement of motor control units without disrupting the entire system.

Example: If a motor control unit needs servicing, it can be safely removed from the panel and replaced without shutting down other units.

Benefit: Reduces downtime and enhances safety by allowing for isolation of specific units during maintenance.

3. System Flexibility and Expansion:

Use: Supports the easy addition of new motor control units as the system grows.

Example: In a factory expanding its production line, new motor starters can be added to the existing MCC panel.

Benefit: Modular design allows for easy system expansion and reconfiguration to meet changing operational needs.

4. Protection and Safety:

Use: Provides protection against electrical faults, such as overloads, short circuits, and ground faults.

Example: Overload relays and circuit breakers within the panel protect motors from damage due to excessive current or voltage spikes.

Benefit: Ensures the safe operation of motors and other equipment, reducing the risk of equipment failure and electrical hazards.

5. Centralized Monitoring and Control:

Use: Centralized location for monitoring motor performance and operational status.

Example: Operators can monitor the status of all connected motors, including parameters like voltage, current, and power consumption, from a single point.

Benefit: Simplifies the management of multiple motors, improves troubleshooting, and enhances overall system reliability.

6. Integration with Automation Systems:

Use: Integration with Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems for automated control.

Example: In an automated manufacturing process, the MCC panel can be linked to a PLC that controls the sequence of motor operations.

Benefit: Enables sophisticated control schemes, remote monitoring, and automation, increasing process efficiency and reducing manual intervention.

7. Space-Efficient Design:

Use: Compact and organized design allows for efficient use of space in control rooms and electrical enclosures.

Example: In an industrial facility with limited space, a drawout MCC panel can consolidate motor control functions in a minimal footprint.

Benefit: Saves valuable space, making it ideal for environments where space is a premium.

8. Customizable Control Options:

Use: Provides customizable control schemes tailored to specific application needs.

Example: Different motor starting methods, such as Direct-On-Line (DOL), Star-Delta, or Variable Frequency Drives (VFD), can be incorporated based on the motor and application requirements.

Benefit: Enhances operational flexibility, allowing for tailored solutions that optimize performance and energy efficiency.

9. Enhanced Operational Safety:

Use: Improves operational safety through features like interlocking mechanisms and automatic disconnection when units are drawn out.

Example: Prevents accidental contact with live parts, reducing the risk of electrical shock during maintenance.

Benefit: Ensures that maintenance personnel can safely access and work on individual motor control units.

10. Versatile Applications:

Use: Applicable in a wide range of industries including manufacturing, oil and gas, water treatment, mining, and more.

Example: Used in oil refineries to control pumps and compressors, ensuring smooth and safe operation of critical processes.

Benefit: Adaptable to various industrial environments, making it a versatile solution for motor control.

11. Reliability and Longevity:

Use: Designed for long-term operation with reliable performance under demanding conditions.

Example: In a heavy-duty industrial setting, a drawout MCC panel can withstand harsh environmental conditions and continuous operation.

Benefit: Provides reliable motor control, minimizing the risk of operational downtime due to equipment failure.

In summary, Drawout MCC Panels are used to manage and control multiple motors efficiently, providing ease of maintenance, flexibility, safety, and integration with modern automation systems. They are essential in industrial settings where minimizing downtime and maintaining operational reliability are critical.