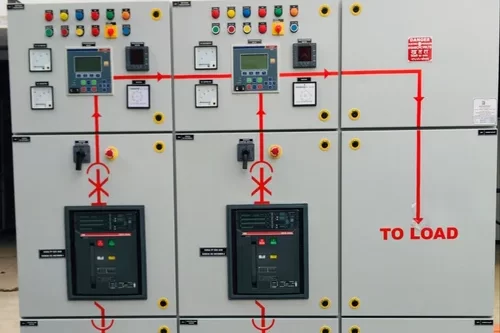

Synchronizing Panel

A Synchronizing Panel is a specialized electrical panel used to coordinate and manage the operation of multiple generators or power sources in parallel. This panel ensures that these power sources work together seamlessly and provide a stable and reliable power supply. Synchronizing panels are crucial in applications where continuous power is essential, such as in data centers, hospitals, industrial plants, and large commercial buildings. Here’s a detailed explanation of the synchronizing panel and its components:

Key Features of a Synchronizing Panel:

1.Synchronization:

Purpose: Ensures that multiple generators or power sources operate in sync, matching their voltage, frequency, and phase.

Function: Adjusts the output of each generator to align with the others before connecting them to the load, preventing power surges or electrical faults.

2.Load Sharing:

Purpose: Distributes the electrical load evenly among multiple generators or power sources.

Function: Balances the load to prevent overloading any single generator, extending the life of each unit and improving overall system reliability.

3.Automatic Transfer:

Purpose: Automatically transfers the load from one generator to another in the event of a failure or maintenance.

Function: Ensures continuous power supply by switching to an available generator without interrupting the power to critical systems.

4.Protection:

Purpose: Provides protection against electrical faults and abnormal operating conditions.

Function: Includes features such as overload protection, short-circuit protection, and isolation of faulty generators to safeguard the system.

5.Control and Monitoring:

Purpose: Provides centralized control and monitoring of the generators and power sources.

Function: Allows operators to monitor performance parameters, control the operation of the generators, and make adjustments as needed.

In a Synchronizing Panel, various electrical abbreviations and symbols are used to represent components, functions, and control elements. Here’s a comprehensive list of common abbreviations and symbols found in synchronizing panels:

SYNC – Synchronization

Function: Refers to the process of aligning multiple generators or power sources in terms of voltage, frequency, and phase before connecting them to the load.

AVR – Automatic Voltage Regulator

Function: Regulates the output voltage of each generator to maintain a stable voltage level across the system.

FRC – Frequency Regulator Controller

Function: Manages the generator’s speed to match the frequency of other generators.

PSM – Phase Sequence Monitor

Function: Ensures that the phase sequence of the generators matches before synchronization.

LSC – Load Sharing Controller

Function: Distributes the electrical load evenly among multiple generators to prevent overloading.

ATS – Automatic Transfer Switch

Function: Automatically switches the load between different power sources or generators based on pre-set conditions.

CT – Current Transformer

Function: Measures the current flowing through the circuit and provides a scaled-down signal for monitoring and control.

PT – Potential Transformer

Function: Measures the voltage in the circuit and provides a scaled-down signal for monitoring and control.

RTD – Resistance Temperature Detector

Function: Measures the temperature of the generator or surrounding environment.

CB – Circuit Breaker

Function: Provides protection against overcurrent and short-circuit conditions in the circuit.

MCCB – Molded Case Circuit Breaker

Function: Protects electrical circuits from overloads and short circuits.

RCD – Residual Current Device

Function: Detects earth faults and disconnects the circuit to prevent electric shock.

HMI – Human-Machine Interface

Function: Provides a user interface for interacting with the synchronizing panel, including configuration and monitoring.

PLC – Programmable Logic Controller

Function: Manages and automates the synchronization process based on programmed logic.

SCADA – Supervisory Control and Data Acquisition

Function: A system for real-time monitoring and control of the synchronizing panel through a centralized interface.

GCB – Generator Circuit Breaker

Function: A circuit breaker specifically used for protection of generators.

1.Synchronization Controller Symbol:

Symbol: Typically represented by a rectangle or box with the label “SYNC” or an icon depicting a controller.

Function: Manages the synchronization process for the generators.

2.Automatic Voltage Regulator (AVR) Symbol:

Symbol: A rectangle with the letters “AVR” or an icon depicting a voltage regulator.

Function: Regulates the output voltage of the generator.

3.Frequency Controller Symbol:

Symbol: A rectangle with the letters “FRC” or an icon depicting a frequency regulator.

Function: Controls the frequency of the generator to match other units.

4.Phase Sequence Monitor Symbol:

Symbol: A rectangle with the letters “PSM” or an icon depicting a phase monitor.

Function: Monitors and ensures correct phase sequence.

5.Load Sharing Controller Symbol:

Symbol: A rectangle with the letters “LSC” or an icon depicting load distribution.

Function: Manages the distribution of load among generators.

6.Automatic Transfer Switch (ATS) Symbol:

Symbol: A rectangle or switch icon with the letters “ATS.”

Function: Automatically switches the load between power sources.

7.Current Transformer (CT) Symbol:

Symbol: A circle with a line passing through it or a rectangle with the letters “CT.”

Function: Measures current and provides a scaled-down signal.

8.Potential Transformer (PT) Symbol:

Symbol: A rectangle or circle with the letters “PT.”

Function: Measures voltage and provides a scaled-down signal.

9.Resistance Temperature Detector (RTD) Symbol:

Symbol: A rectangle or circle with the letters “RTD” or a thermometer icon.

Function: Measures temperature.

10.Circuit Breaker (CB) Symbol:

Symbol: A rectangle or square with the letters “CB” inside.

Function: Provides overcurrent protection.

11.Generator Circuit Breaker (GCB) Symbol:

Symbol: A rectangle with the letters “GCB” or an icon depicting a generator.

Function: Protects generators from electrical faults.

12.Residual Current Device (RCD) Symbol:

Symbol: A rectangle with the letters “RCD” or a standard RCD icon.

Function: Detects earth faults and prevents electric shock.

13.Human-Machine Interface (HMI) Symbol:

Symbol: A screen or panel icon with the letters “HMI.”

Function: Provides a user interface for monitoring and control.

14.Programmable Logic Controller (PLC) Symbol:

Symbol: A rectangle with the letters “PLC” or an icon depicting a logic controller.

Function: Manages and automates control processes.

15.Supervisory Control and Data Acquisition (SCADA) Symbol:

Symbol: A rectangle or screen icon with the letters “SCADA.”

Function: Centralized system for monitoring and control.

16.Alarm Symbol:

Symbol: A triangle with an exclamation mark or a bell icon.

Function: Indicates an alarm or fault condition.

17.Indicator Light Symbol:

Symbol: A circle or square with a lightbulb icon.

Function: Represents an indicator light showing the status of the system.

18.Emergency Stop Symbol:

Symbol: A red button icon with “E-STOP” or similar marking.

Function: Provides an emergency shutdown option.

A Synchronizing Panel is essential in managing and coordinating multiple power sources, particularly generators, to ensure a stable and reliable power supply. Here’s a detailed overview of the uses and applications of a synchronizing panel:

1. Parallel Operation of Generators:

Purpose: Enables multiple generators to operate in parallel, ensuring that their outputs are synchronized in terms of voltage, frequency, and phase.

Use: Useful in settings where continuous power is critical and multiple generators are required to handle varying loads or provide redundancy.

2. Load Sharing:

Purpose: Distributes the electrical load evenly among the generators.

Use: Prevents any single generator from being overloaded, thus extending the life of each unit and improving overall system reliability and efficiency.

3. Automatic Load Transfer:

Purpose: Automatically transfers the load between different power sources in case of a generator failure or maintenance.

Use: Ensures uninterrupted power supply by switching to an available generator without affecting the connected load.

4. Power Redundancy:

Purpose: Provides backup power to critical systems.

Use: Ensures continuous operation of essential services such as data centers, hospitals, and industrial processes in case of primary power source failure.

5. Seamless Integration with Utility Power:

Purpose: Allows for synchronization with the main utility power grid.

Use: Facilitates the transition between generator power and utility power, ensuring a stable and uninterrupted power supply.

6. Emergency Power Supply:

Purpose: Ensures a reliable backup power source during emergencies or power outages.

Use: Provides emergency power to critical infrastructure and systems, such as fire alarm systems, emergency lighting, and medical equipment.

7. Improved Efficiency:

Purpose: Optimizes the operation of generators by balancing the load and running them at their most efficient operating points.

Use: Reduces fuel consumption and operating costs by ensuring that generators are used efficiently.

8. Maintenance Flexibility:

Purpose: Allows for the maintenance of individual generators without interrupting power to the load.

Use: Facilitates scheduled maintenance and repairs by enabling the removal of one generator from service while others continue to operate.

9. System Protection:

Purpose: Protects generators and associated equipment from electrical faults and abnormal operating conditions.

Use: Includes features such as overcurrent protection, short-circuit protection, and isolation of faulty generators to safeguard the system.

10. Real-Time Monitoring and Control:

Purpose: Provides centralized monitoring and control of multiple generators and power sources.

Use: Allows operators to monitor performance parameters, control generator operation, and make adjustments as needed from a central location.

11. Remote Monitoring and Management:

Purpose: Enables remote access and management of the synchronizing panel.

Use: Allows operators to monitor and control generators and power sources from a remote location, enhancing operational flexibility and response times.

12. Integration with Automation Systems:

Purpose: Integrates with other control systems, such as PLCs and SCADA systems, for coordinated operation.

Use: Facilitates automation of complex power management tasks, providing centralized control and monitoring capabilities.

13. Power Quality Management:

Purpose: Ensures that power quality is maintained across the system.

Use: Addresses issues related to voltage fluctuations, frequency deviations, and phase imbalances, improving the overall reliability and stability of the power supply.

14. Customized Operating Modes:

Purpose: Provides flexibility in operational settings and control strategies.

Use: Allows for customization of operating modes based on specific application requirements, such as peak shaving, load shedding, or standby operation.

15. Reduced Operational Downtime:

Purpose: Minimizes downtime by providing a reliable and redundant power supply.

Use: Ensures continuous operation of critical systems and processes, reducing the risk of outages and disruptions.